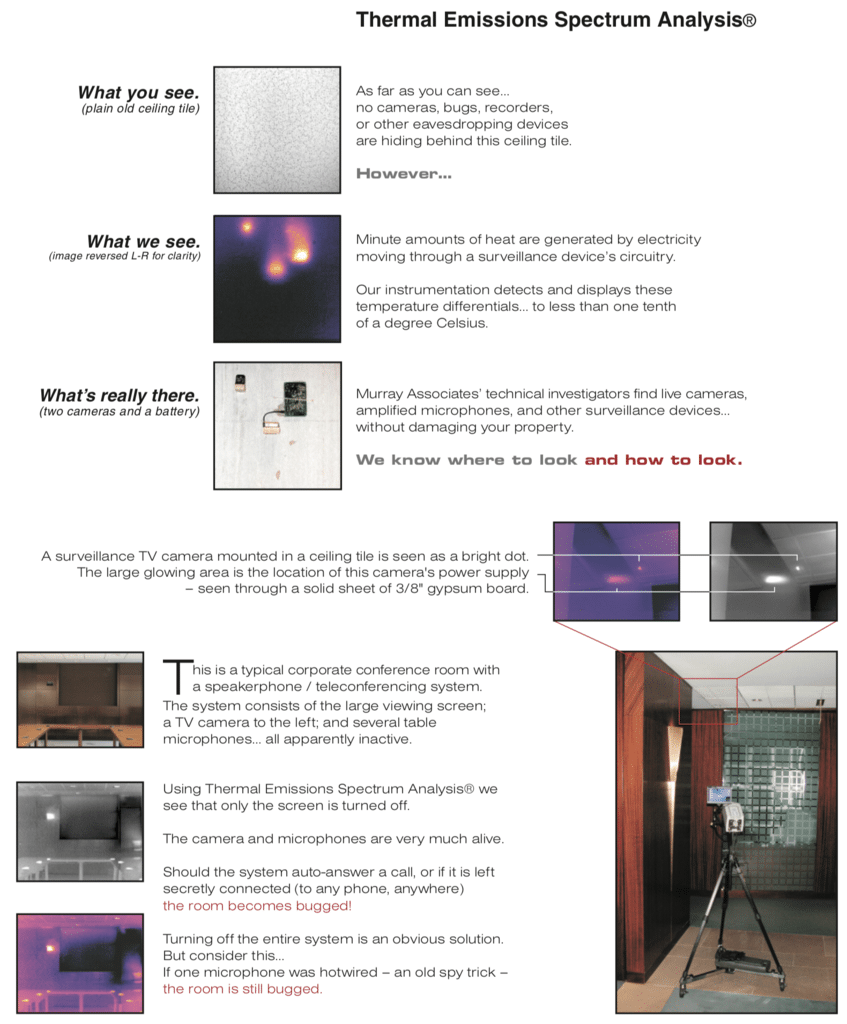

Thermal Emissions Spectrum Analysis as a Detection Technique

for Finding Covert Electronic Surveillance Devices

Infrared bug detection was pioneered by Murray Associates at the turn of the century. Here are some details as to how this technique works.

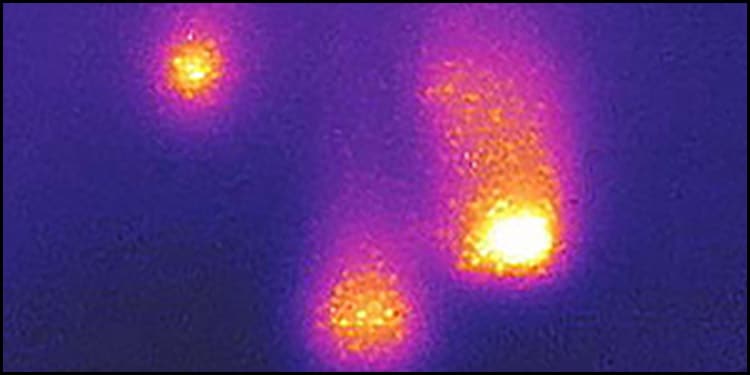

Heat is the graveyard of electricity. It is where expended electrons go to die. Look in the right places for these graveyards, and start digging. You just might find buried electronic surveillance devices… audio bugs, micro-sized video cameras, recorders, wiretap transmitters, and the video transmitters which move private sights and sounds to illicit eyes and ears.

The premise is simple. When electricity moves through any electronic circuit, some of the energy converts to heat. This is caused by resistance which is inherent in all circuits. Cooling a circuit to a temperature of absolute zero (0º Kelvin / -450º Fahrenheit) is the only way to eliminate resistance. Fortunately, refrigeration of electronic circuits is not practical in the real world, or the shadowy world of espionage. Electrons will meet with resistance. Heat will be generated. Heat will migrate. Heat can be detected, thus a infrared bug detection becomes a reality.

Heat may be generally thought of as light waves that are too low in frequency for our eyes to see. The term infrared is used to describe this phenomena. Neither can we hear radio waves, dog whistles and bats’ echo-locating sounds, because the frequencies are either too high, or too low, for our ears to hear. To perceive these out-of-our-perception frequencies we need some type of instrument which will detect and then convert them into something we can perceive. An infrared thermal imager is basically a converter – taking low frequency light waves and converting them to the light frequencies we can see. Loosely speaking, radios perform the same function for our ears.

Types of Infrared Thermal Imagers

Imagers may be described as falling into two broad – sensitivity / price defined – categories…

Level I

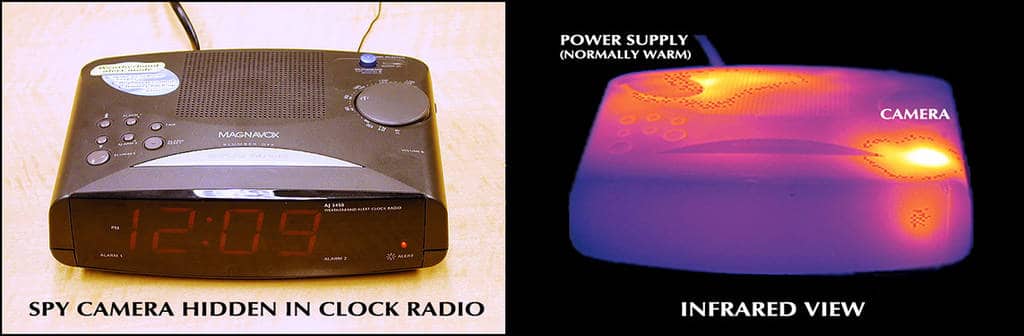

Clock Radio Infrared Comparison

Low sensitivity: 1 degree C. to .07 degree C.

Resolution: 320 x 240 resolution or less

For many years military, police, fire and electrical maintenance workers have been using Level I thermal imagers to assist with: night surveillance, search and rescue, and finding human bodies in smoke-filled rooms. Other uses include: predictive maintenance, building heat-loss surveys and locating buried bodies. The majority of imagers sold are Level I because sensitivity is not an issue for the purchasers. Just being able to see a temperature difference of several degrees is more than adequate for their applications.

Thermal image shows conference room table microphones are live (white = hot)

Level II

High sensitivity: <.008 degree C.

Resolution: greater than 320 x 240 resolution

Cameras in this range are used in military satellites, medical diagnostics labs, and now… Technical Surveillance Countermeasures (TSCM).

Infrared cameras are also separated into groups according to what part of the infrared spectrum they detect…

Near Infrared (nearIR) Wavelength: .75 – 1.1 microns

Not applicable to TSCM work as a heat detector.

Short Wave Infrared (SWIR) Wavelength: 1.1 – 2.5 microns

Somewhat applicable to TSCM work as a heat detector.

Medium Wave Infrared (MWIR or Mid-IR) Wavelength: 2.5 – 7 microns

Ideal for infrared bug detection as a heat detector.

Long Wave Infrared (LWIR) Wavelength: 7 – 15 microns

Applicable to TSCM work as a heat detector.

Only MWIR and LWIR cameras are called thermal imagers.

The amount of heat radiated by a bugging device can be quite large, or quite small. The sensitivity measurement required to see the smallest heat emitters is in the order of eighteen-thousandths of a degree Celsius or less! By comparison, human touch can distinguish a temperature difference of only about two degrees Celsius by most accounts.

Technical surveillance countermeasures (TSCM) practitioners have suspected for a long time that heat sensing would be an aid in surveillance device detection. Unfortunately, portable instrumentation of sufficient sensitivity and resolution was not available until the late 1990’s. The first and most common imagers – Level I – were not effective enough to be useful for bug detection work.

Infrared Bug Detection Science Catches Up

Level II imagers are now generally available. These instruments are truly useful. Cost is the only thing standing in the way of complete acceptance and adoption to TSCM toolkits. The good news is that rapid advancements in the field of thermal imaging sensors, combined with increased demand, has caused prices to fall into acceptable ranges since they were first introduced.

Advantages of Thermal Emissions Spectrum Analysis

There are three stunning advantages that a Level II infrared bug detection thermal imager brings to a TSCM inspection…

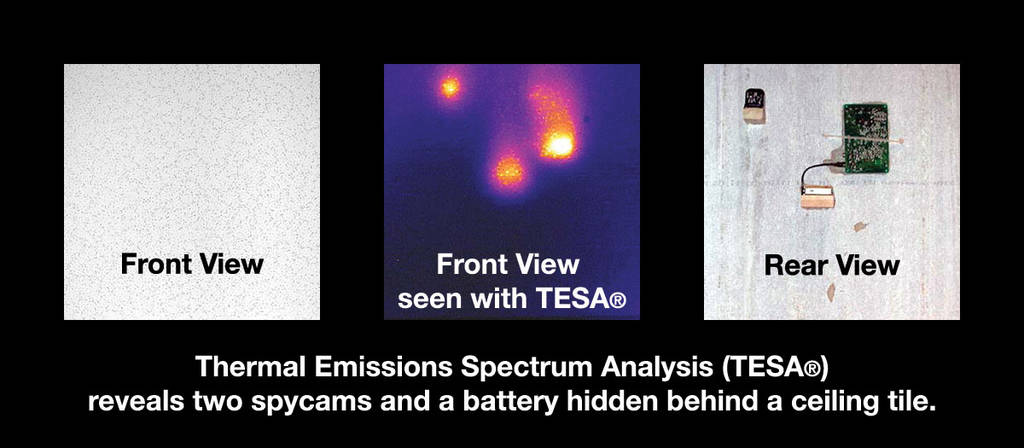

1. The ability to see slightly elevated temperatures. Example: Inspect 40,000 square feet of ceiling tiles in less than five minutes to find a 1 inch square video camera embedded in one tile.

2. The ability to see density differences in materials. Example: Inspect 40,000 square feet of ceiling tiles in less than five minutes and find where a video camera was – at one time – embedded in a ceiling tile.

3. The ability to see through some materials. Example: Certain materials which appear opaque in normal light become quite transparent when viewed at infrared wavelengths.

Key Specifications

Thermal imaging technology is advancing at a rapid rate. To keep the information presented here from becoming dated, specific camera manufacturers and models are not mentioned. There are, however, two key specifications to look for when purchasing a thermal imager…

Sensitivity – Usually stated as NEdT (noise equivalent differential temperature), a figure which represents the temperature difference required to produce a signal equal to the imager’s internal circuit noise. For TSCM purposes, the lower the number, the better.

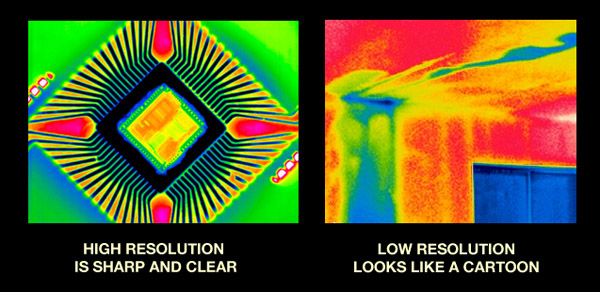

Resolution – This specification determines the sharpness of the picture you will see. Just like regular digital photography cameras, the more pixels the better. Currently, most cameras come with either 128 x 128, 320 x 256, or 640 x 512 pixel arrays. 128 x 128 is barely inadequate for TSCM inspections.

Common Misconceptions

Misconception #1: An imager of inferior sensitivity can be used if the area being inspected is either quickly heated or cooled just before viewing. This is does not apply to infrared bug detection. The technique does not increase the temperature differential between a covert surveillance device and its surroundings. Small electronic objects do not have thermal mass. They will track with the temperature change as quickly as most other objects in the area.

The concept that a Level I thermal imager can be used in this manner has its roots in applications where the objects being viewed have great thermal mass compared to the features of interest. Finding buried bodies, and infrared examination of the Pyramids are two good examples of this.

Misconception #2: “I tried a Level I imager. It saw a hidden video camera. So why not just use it? It’s cheaper.”

Yes, less sensitive imagers will see the very warmest covert surveillance devices, like some video cameras. They are not, however, capable of seeing a majority of the other surveillance devices, or the slight density differences in enclosure materials which give away current and former installations. To be an effective TSCM instrument, a thermal imager ideally needs have an NEdT of less than 60 milliKelvins, preferable much less.

Conclusion

Thermal Emissions Spectrum Analysis is not a replacement for any other TSCM inspection procedure.

It is an additional technique which greatly enhances effectiveness and will allow for the most thorough inspection possible when the time allocated for the inspection is limited.

Examples of Infrared Bug Detection

###

Murray Associates is an independent security consulting firm, providing eavesdropping detection and counterespionage services to business, government and at-risk individuals.

Headquartered in the New York metropolitan area, a Murray Associates team can assist you quickly, anywhere in the United States, and internationally.

EXTRAS:

• More security tips, spy and privacy news at spybusters.blogspot.com. Be sure to sign up for the free email updates.

• Concerned about Spy Cameras? Learn how to detect hidden cameras.